ABOUT US

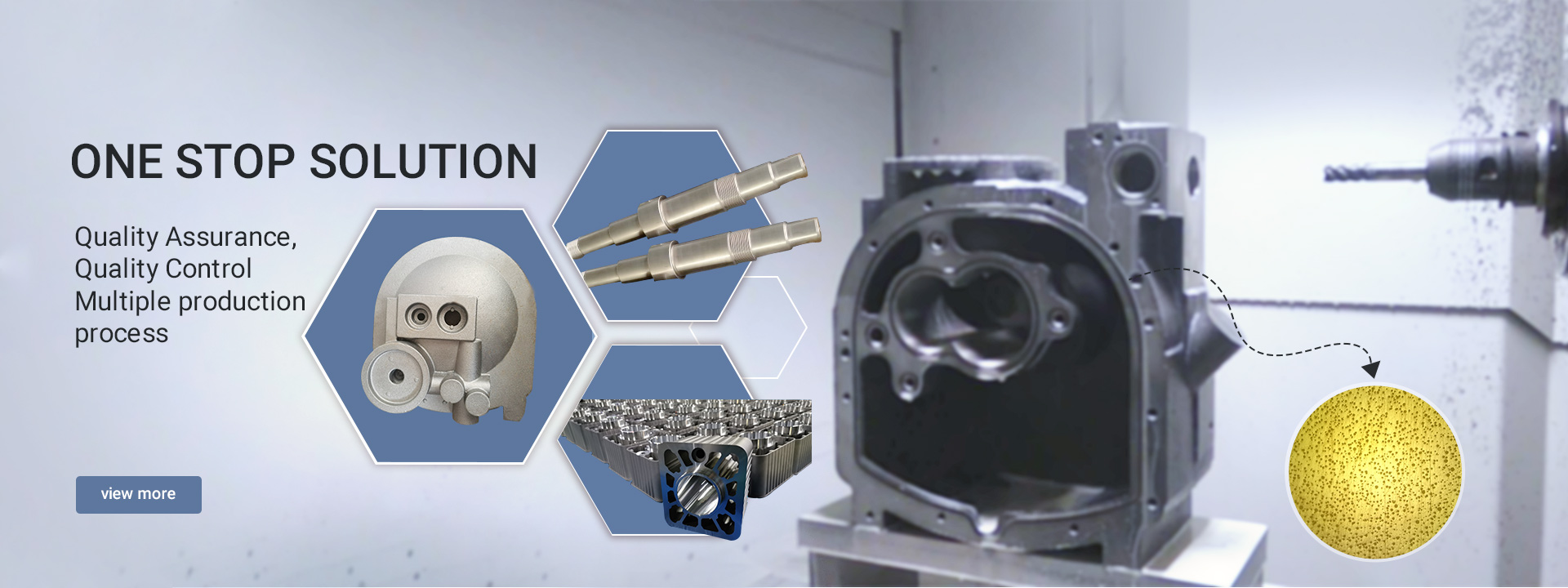

Neuland is a company manufacturing and marketing of metal products for nearly 20 years.

The company has been supplying products in materials cast iron, steel, stainless steel, aluminum, copper etc by production methods sand casting, die casting, lost wax casting and die forging and precision machining. Assembling and surface coating service are also available.

And over the past years, the company has grown up as a whole process solution provider for any metal products in various industries. Either your drawings can be shaped into products, or even your idea can be realized into a satisfactory product starting designing to shipping. Moreover, our engineering team is capable and more than happy to provide our proposals to you on valuable change of production method and material to best fulfill the cost reduction and function of a product.

NEWS

-

The main casting process

The main casting process includes: Metal smelting, model making, pouring solidification and demoulding cleaning. The main materials used for casting are cast steel, cast iron, cast nonferrous alloys (copper, aluminum, zinc, lead, etc.). The most commonly used casting method i... -

The application industries of nickel-base...

Nickel-based alloys are widely used in many industries due to their excellent high temperature resistance, corrosion resistance, high strength and other properties. The following is a detailed introduction: 1. **Aerospace field**: - **Key component manufacturing**: Nickel-ba... -

Material classification of high-temperatu...

1. Classification by matrix element type: Iron-based high-temperature alloy: The matrix is iron, with a small amount of alloy elements such as nickel and chromium added. This type of alloy is also called heat-resistant alloy steel, which can be divided into martensite, aust... -

High-frequency quenching

High-frequency quenching is mostly used for surface quenching of industrial metal parts. It is a metal heat treatment method that generates a certain induction current on the surface of the workpiece, quickly heats the surface of the part, and then quickly quenches it. Inducti... -

Worm gear

Worm gear mechanisms are often used to transmit motion and power between two staggered axes. The worm wheel and worm are equivalent to the gear and rack in their middle plane, and the worm is similar in shape to the screw. Many worm gears have an interesting feature that othe...

LATEST PRODUCT

Get the latest news delivered daily!

Give us your email and you will be daily updated with the latest events, in detail!