Low MOQ for Cast Iron Foundry - CNC machining parts – Neuland Metals

Low MOQ for Cast Iron Foundry - CNC machining parts – Neuland Metals Detail:

CNC machining is a digital manufacturing technology which pre-programmed computer software dictates the movement of factory tools and machinery: it produces high-accuracy parts with excellent physical properties directly from a CAD file. The process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts. Due to the high level of automation, CNC is price-competitive for both one-off custom parts and medium-volume productions.

The most frequently used machines in CNC systems include the following: CNC Mills, Lathes, Plasma Cutters, Electric Discharge Machines and Water Jet Cutters. As plenty of CNC machine video demonstrations have shown, the system is used to make highly detailed cuts out of metal pieces for industrial hardware products. In addition to the aforementioned machines, further tools and components used within CNC systems include: Embroidery machines, Wood routers, Turret punchers, Wire-bending, machines, Foam cutters, Laser cutters, Cylindrical grinders,3D printers, Glass cutters. When complicated cuts need to be made at various levels and angles on a work piece, it can all be performed within minutes on a CNC machine. As long as the machine is programmed with the right code, the machine functions will carry out the steps as dictated by the software. Providing everything is coded according to design, a product of detail and technological value should emerge once the process has finished.

CNC machining is one of the most critical functions of the manufacturing sector, from the production of computer parts and fasteners to auto parts and aerospace components. Without the high-tech capabilities unique to CNC machines, various components seen on everyday household items would be nearly impossible to produce.

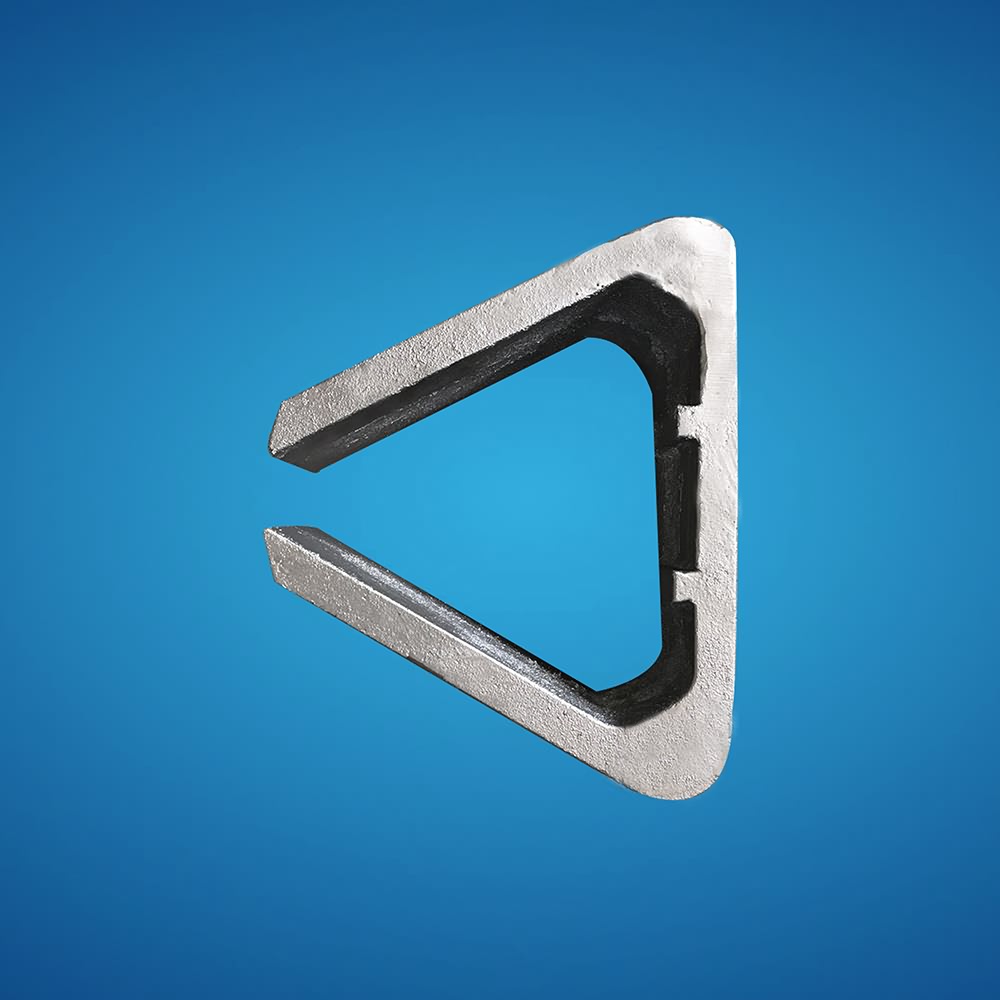

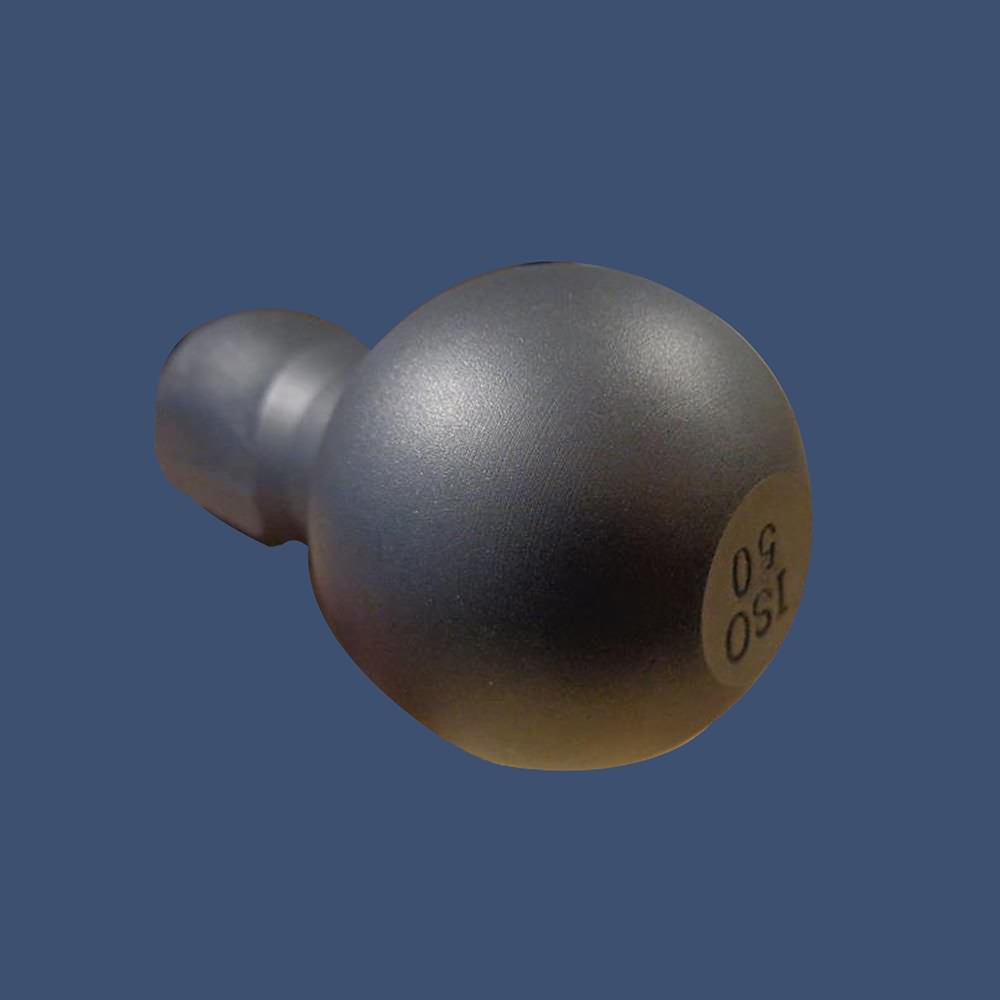

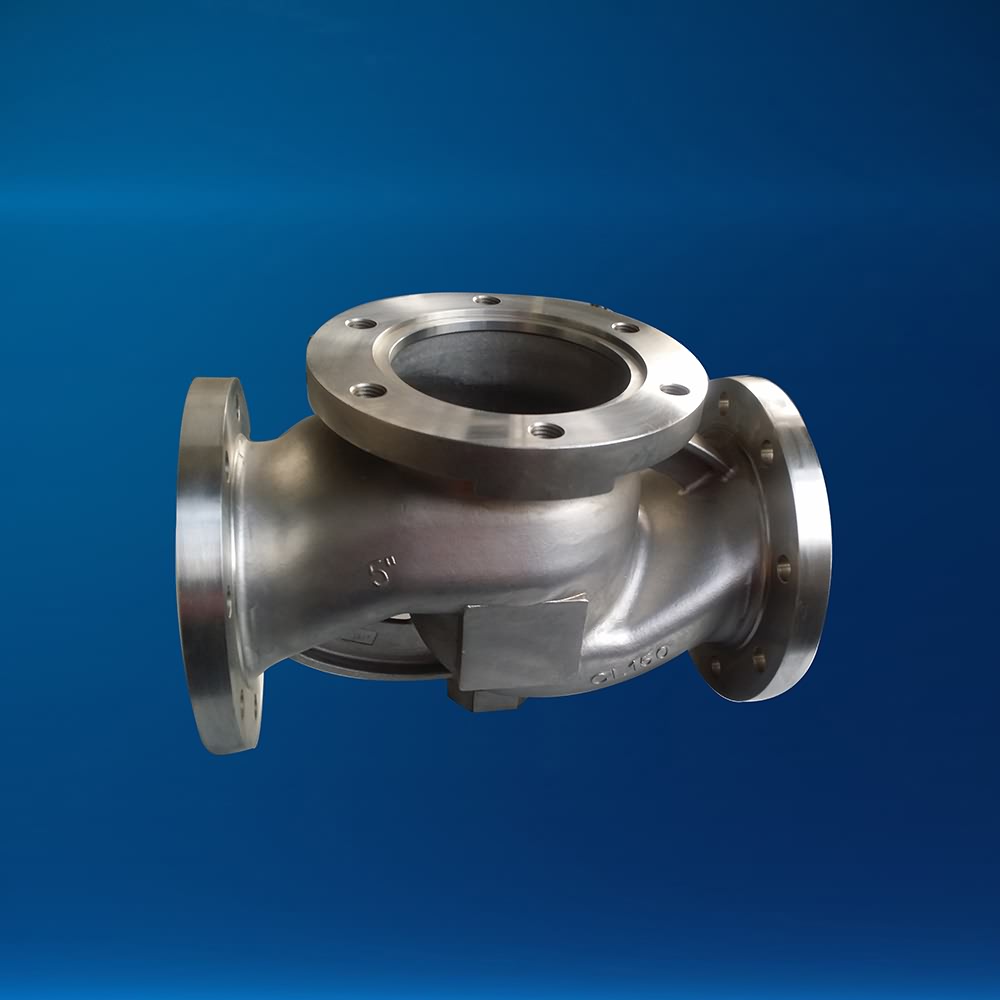

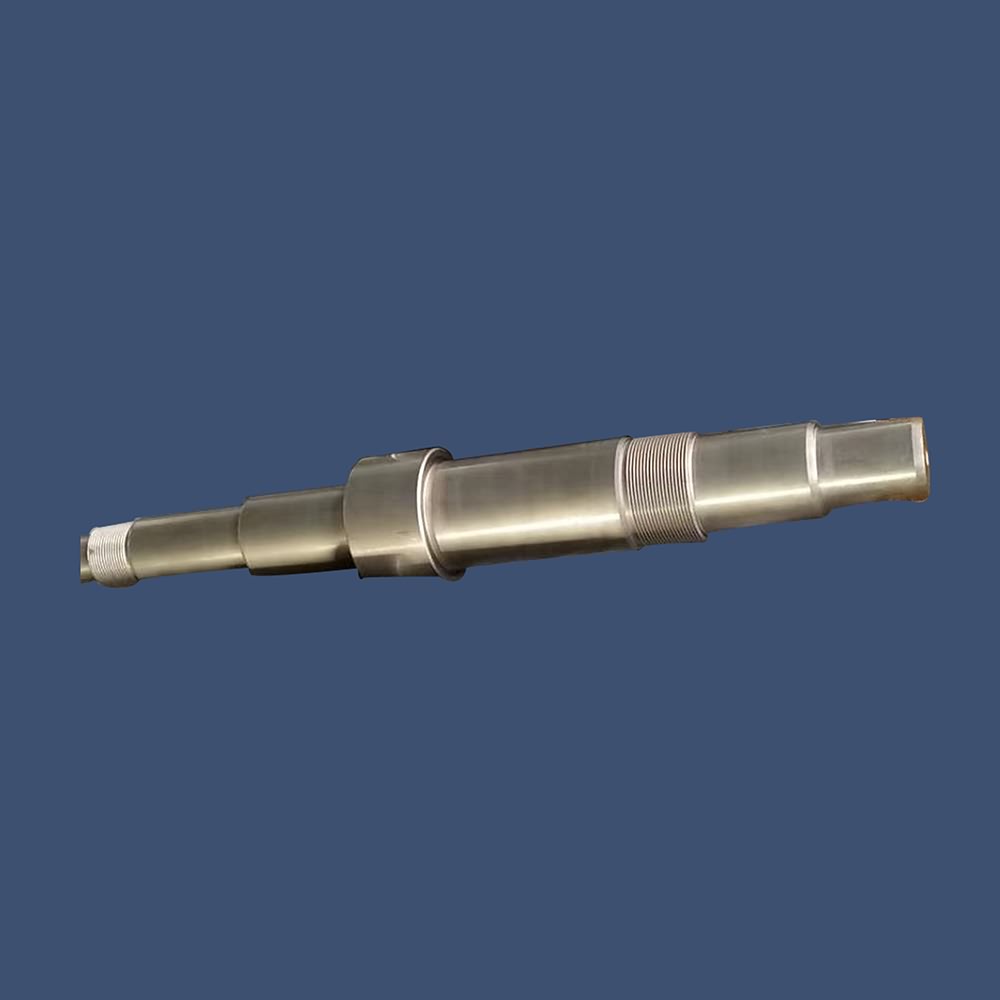

Product detail pictures:

Related Product Guide:

Every single member from our large efficiency revenue team values customers' wants and company communication for Low MOQ for Cast Iron Foundry - CNC machining parts – Neuland Metals , The product will supply to all over the world, such as: Montpellier, New Zealand, Benin, We offer OEM services and replacement parts to meet the varying needs of our customers. We offer competitive price for quality products and we will make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.