OEM China Copper Investment Casting - Metal stamping parts Stainless steel, alloy steel, carbon steel. Aluminum, copper, iron – Neuland Metals

OEM China Copper Investment Casting - Metal stamping parts Stainless steel, alloy steel, carbon steel. Aluminum, copper, iron – Neuland Metals Detail:

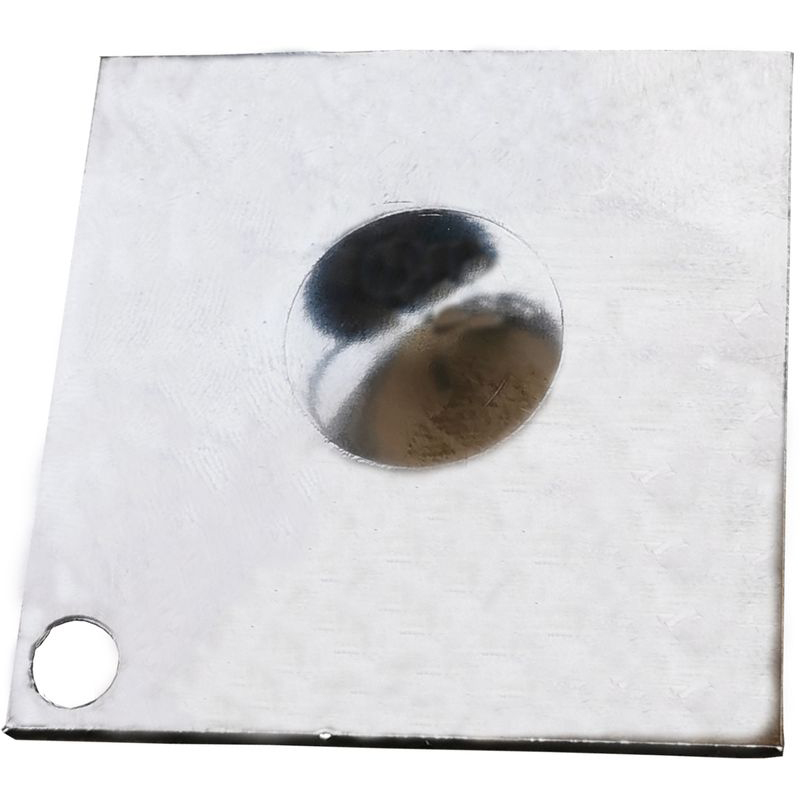

Product name: Metal stamping parts

Material: Stainless steel, alloy steel, carbon steel. Aluminum, copper, iron

Q235, 45#steel, 40Cr, 35CrMo, 42CrMo. C20, SS304, SS316

Production process: Stamping is a kind of production technology which makes sheet metal directly subject to deformation force and deform with the help of conventional or special stamping equipment, so as to obtain a certain shape, size and performance of product parts. Sheet metal, die and equipment are the three elements of stamping process. Stamping is a kind of metal cold deformation processing method. Therefore, it is called cold stamping or sheet metal stamping, referred to as stamping. It is one of the main methods of metal plastic processing (or pressure processing), and also belongs to material forming engineering technology. Bending, deep drawn,

Unit Weight: 0.05kg-20kg, 0.1lbs-40lbs

Size scope: 50~1000mm, 2~40 inch

Customizable or not: Yes

Available service: Design optimization, OEM, precision machining, heat treatment, cnc machining, milling, drilling. Painting, powder coating, electroless nickel plating. Zinc Plating, E-coating. HDG, hot galvanizing

Packing: Carton, plywood cases, pallets

Certificate: ISO9001:2008

Inspection report: Dimension report. Material report including chemical contents, tensile strength, yield strength and hardness. X-ray test report, Ultrasonic test report and Magnetic particle test available upon request.

Advantage:

1, The production efficiency of stamping process is high, and the operation is convenient, and it is easy to realize mechanization and automation. This is because stamping depends on the stamping die and stamping equipment to complete the processing. The stroke times of ordinary press can reach dozens of times per minute, and the high-speed pressure can reach hundreds or even thousands of times per minute, and each stamping stroke can get a stamping part.

2, as like as two peas are used to ensure the stamping parts’ surface quality, the die life is generally longer. The stamping quality is stable and interchangeability is good, and it has the same characteristics.

3, Stamping can process parts with large size range and complex shape, such as stopwatch of clock and watch, automobile longitudinal beam, panel, etc. with the cold deformation hardening effect of material during stamping, the stamping strength and stiffness are higher.

4, Generally, stamping does not produce chips and chips, consumes less materials, and does not need other heating equipment, so it is a kind of material saving and energy-saving processing method, and the cost of stamping parts is lower.

Application:

In aerospace, aviation, military industry, machinery, agricultural machinery, electronics, information, railway, posts and telecommunications, transportation, chemical industry, medical appliances, household electrical appliances and light industry departments, there are stamping processing. Not only the whole industry uses it, but everyone is directly connected with stamping products. For example, there are many large, medium and small stamping parts on airplanes, trains, cars and tractors. Car body, frame, rim and other parts are stamping out. According to statistics, 80% of bicycles, sewing machines and watches are stamping parts; 90% of TV sets, tape recorders and cameras are stamping parts; There are also food metal cans, steel precision boilers, enamel bowls and stainless steel tableware, all of which are stamping products using molds; Even the computer hardware cannot be lack of stamping parts.

Origin: China

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to deliver you with great provider of processing for OEM China Copper Investment Casting - Metal stamping parts Stainless steel, alloy steel, carbon steel. Aluminum, copper, iron – Neuland Metals , The product will supply to all over the world, such as: Swedish, Florida, Portland, To let customers be more confident in us and get the most comfortable service, we run our company with honesty, sincerity and best quality . We firmly believe that it is our pleasure to help customers to run their business more successfully, and that our professional advice and service can lead to more suitable choice for the customers.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!