Quality Inspection for Oem Cast Iron Parts - Metal fabrication / Metal stamping, welding, assembling – Neuland Metals

Quality Inspection for Oem Cast Iron Parts - Metal fabrication / Metal stamping, welding, assembling – Neuland Metals Detail:

Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added process involving the creation of machines, parts, and structures from various raw materials. The popularly applied material in metal fabrication are SPCC, SECC, SGCC, SUS301 and SUS304. And the fabrication production methods include shearing, cutting, punching, stamping, bending, welding and surface treatment, etc.

Metal fabrication projects include everything from hand railings to heavy equipment and machinery. Specific subsectors include cutlery and hand tools; architectural and structural metals; hardware manufacturing; spring and wire manufacturing; screw, nut, and bolt manufacturing; and forging and stamping.

The main features of the fabricated products are light weight, higher strength, inductive, low cost and stable quality. And the fabrication is popularly applied in the industries such as electronics and electric, telecommunication, automotive, medical appliance, to name a few.

The main benefit of metal fabrication shops is the centralization of these many processes that are often required to be performed in parallel via a collection of vendors. A one-stop metal fabrication shop helps contractors limit their need to work with multiple vendors to complete complicated projects.

With more and more fabrication is applied in industries, the designing of the fabrication is becoming a critical procedure during the developing of a fabricated product. Mechanical engineers must have the proper skill to design a the product to meet the demand in terms of function and appearance and low cost for mold.

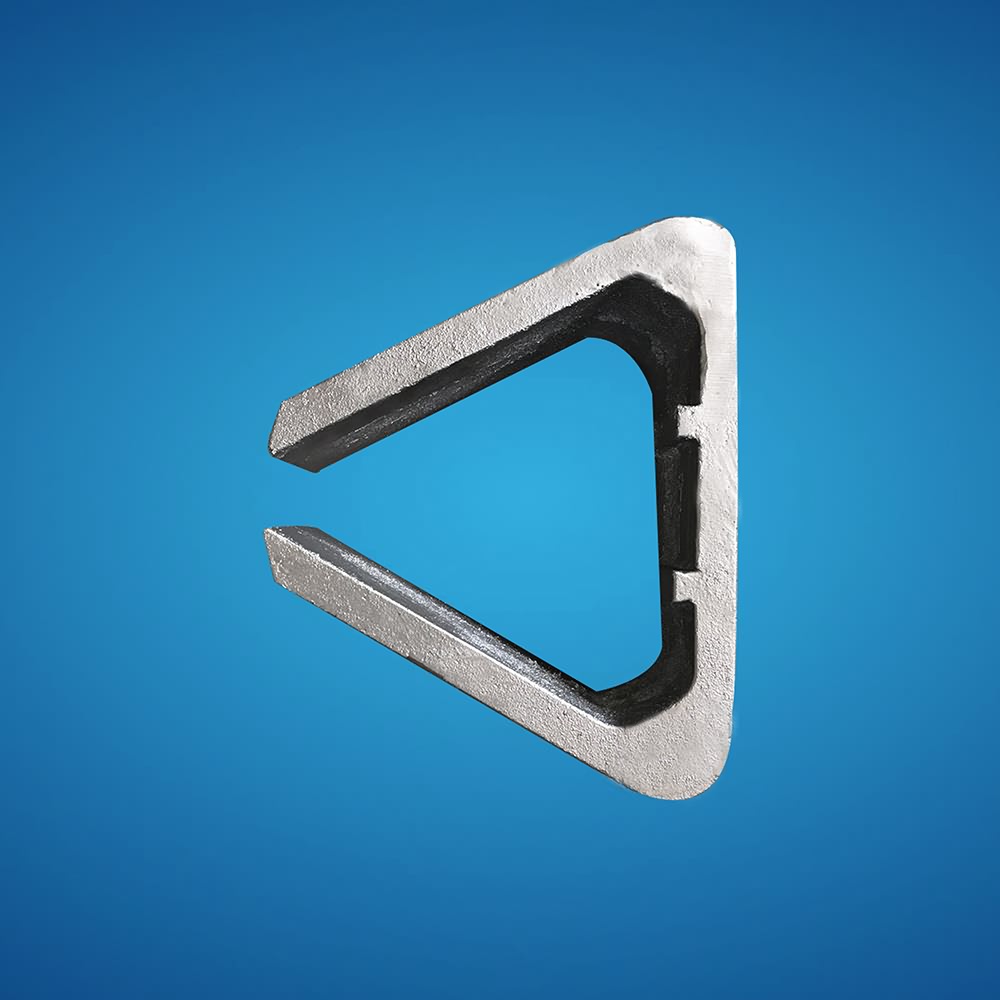

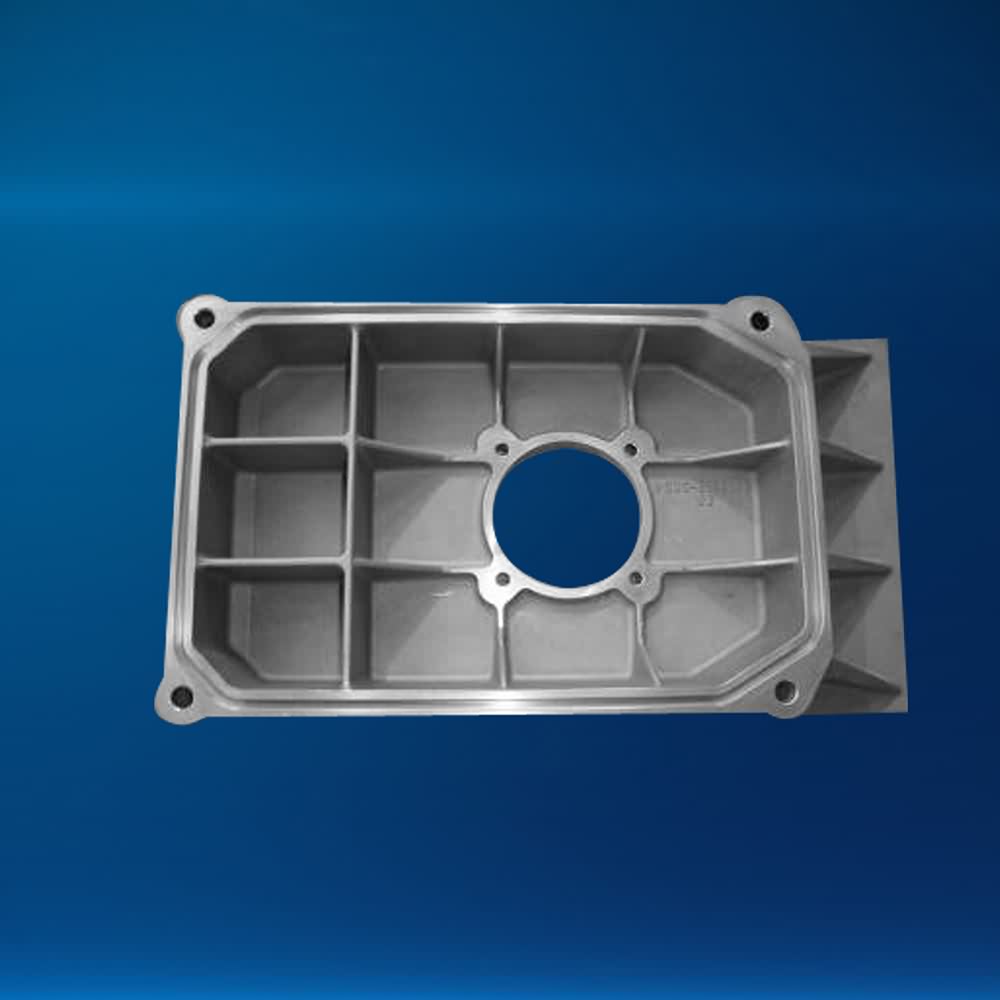

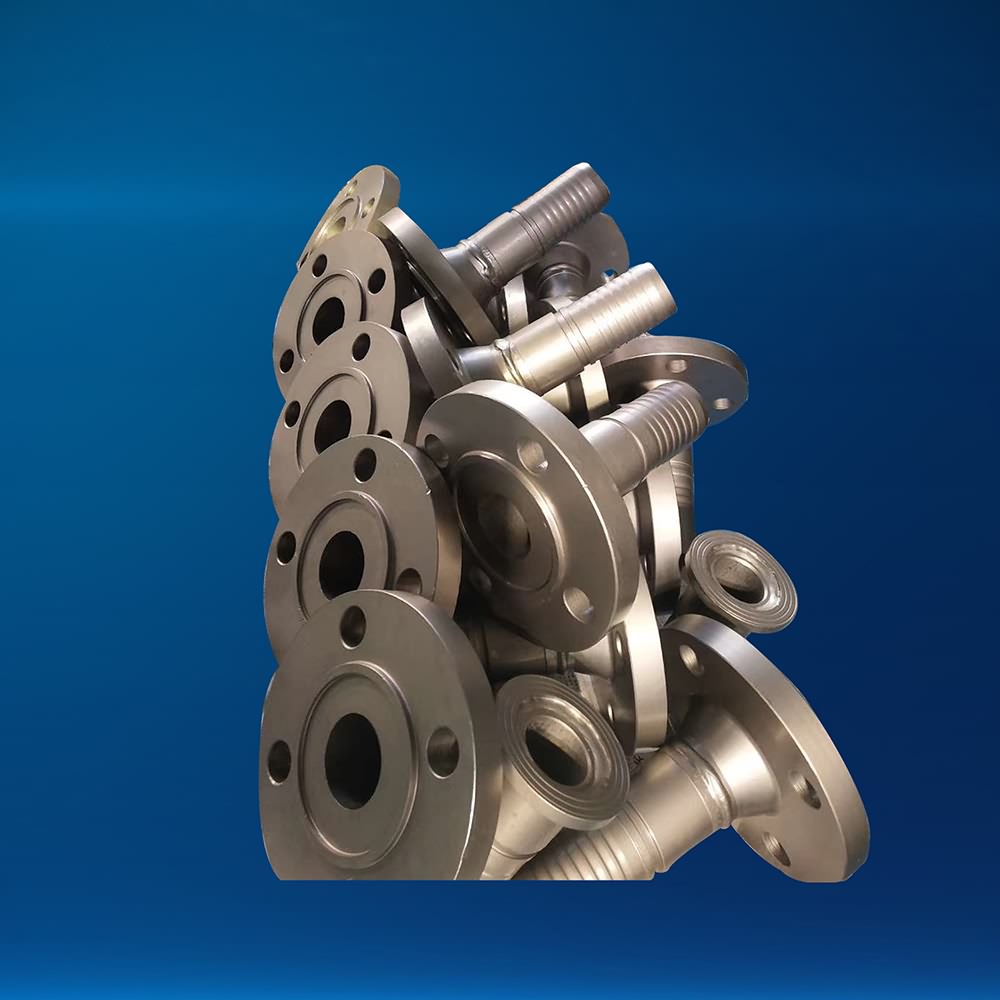

Product detail pictures:

Related Product Guide:

We will constantly satisfy our respected customers with our good excellent, superior value and superior assistance due to we're additional experienced and far more hard-working and do it in cost-effective way for Quality Inspection for Oem Cast Iron Parts - Metal fabrication / Metal stamping, welding, assembling – Neuland Metals , The product will supply to all over the world, such as: Russia, Thailand, Miami, Our solutions are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we now have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!